Housing Special

Products

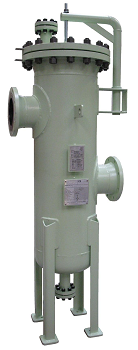

ST: Basket custom made

The ST series single basket filters are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow-rates up to 10,000 m3/h and 2500 # rating.

The ST series single basket filters are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow-rates up to 10,000 m3/h and 2500 # rating.

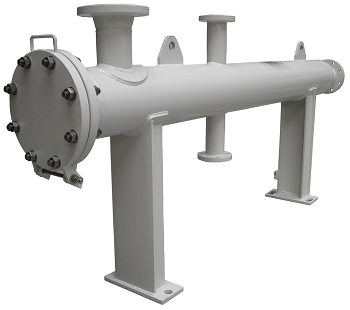

UF: High flow cartridge custom made

The UF series filter cartridges are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow rates up to 2.500 m3/h and 2500 # rating. UF series filters are specifically designed to accommodate high flow cartridges HPF series.

The UF series filter cartridges are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow rates up to 2.500 m3/h and 2500 # rating. UF series filters are specifically designed to accommodate high flow cartridges HPF series.

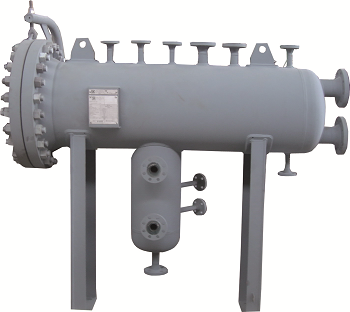

63MT - 68MT: Multi cartridges custom made

The 63MT and 68MT series cartridge filters are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow rates up to 2,000 m3/h and 2500# rating. The 63MT series filters are specifically designed to accommodate cartridges with OD up to 63 mm, while the filters of 68MT series are specifically designed to accommodate cartridges with OD up to 68 mm.

The 63MT and 68MT series cartridge filters are fabricated according to customer specifications and are in accordance with the requirements of the most common international standards (ASME, EN 13445, etc.). They are available in carbon steel, stainless steel or special alloys, for flow rates up to 2,000 m3/h and 2500# rating. The 63MT series filters are specifically designed to accommodate cartridges with OD up to 63 mm, while the filters of 68MT series are specifically designed to accommodate cartridges with OD up to 68 mm.

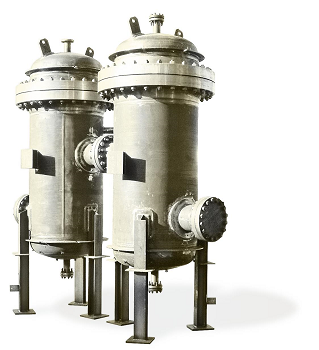

RM: Internally coated custom made

The 63RM and 68RM series cartridge filters are fabricated according to customer specifications and are in accordance with the most common international standards (ASME, EN 13445, etc.). They are made of carbon steel with anti-corrosion lining, for flow rates up to 2,000 m3/h and 2500# rating.

The 63RM and 68RM series cartridge filters are fabricated according to customer specifications and are in accordance with the most common international standards (ASME, EN 13445, etc.). They are made of carbon steel with anti-corrosion lining, for flow rates up to 2,000 m3/h and 2500# rating.

DG: Dry gas filter tailor made

DG series dry gas filters provide an efficient solution to remove dust and solids from process or natural gas steam, at very low pressure drop. The different available configuration allows installing disposable pleated or depth filtering cartridges as well as cleanable pleated wire mesh filtering cartridges.

DG series dry gas filters provide an efficient solution to remove dust and solids from process or natural gas steam, at very low pressure drop. The different available configuration allows installing disposable pleated or depth filtering cartridges as well as cleanable pleated wire mesh filtering cartridges.

GC: Coalescer gas-liquid tailor made

Gas/liquid coalescing system, are designed to provide an adequate solution to the many problems of separation. The choice of coalescing filter type is a function of the presence of solids, liquids, and the efficiency of separation required.

Gas/liquid coalescing system, are designed to provide an adequate solution to the many problems of separation. The choice of coalescing filter type is a function of the presence of solids, liquids, and the efficiency of separation required.

LL: Coalescer liquid-liquid

The LL series liquid/liquid coalescer filters are designed for continuous separation of aqueous phases dispersed in a hydrocarbon stream. LL series filters are available in both vertical and horizontal arrangement. Mainly they are made in the version with double separation stage but are also available in the single stage design.

The LL series liquid/liquid coalescer filters are designed for continuous separation of aqueous phases dispersed in a hydrocarbon stream. LL series filters are available in both vertical and horizontal arrangement. Mainly they are made in the version with double separation stage but are also available in the single stage design.

RVT: Self-Cleaning filters custom made

RVT series filters are designed to remove solid particles from seawater, river water, well water and industrial water. Conceived for continuous filtration, this filter unit is designed to perform fully automatic backwash cycles, using the same filtered fluid. The RVT series filters are suitable for heavy-duty applications such as refineries, offshore, petrochemical plants and steel mills.

RVT series filters are designed to remove solid particles from seawater, river water, well water and industrial water. Conceived for continuous filtration, this filter unit is designed to perform fully automatic backwash cycles, using the same filtered fluid. The RVT series filters are suitable for heavy-duty applications such as refineries, offshore, petrochemical plants and steel mills.

MBW: Self-Cleaning filters modular design tailor made

Modular back-washing feed filter has been designed to prevent fixed bed reactor catalyst fouling. Designed for continuous operation, these filtration units are suitable for automatic backwash with process filtered fluid or with an external fluid, as stated by process requirements and conditions. According to flow-rate, the fluid can be filtered in one or more skid mounted parallel banks, connected by common headers.

Modular back-washing feed filter has been designed to prevent fixed bed reactor catalyst fouling. Designed for continuous operation, these filtration units are suitable for automatic backwash with process filtered fluid or with an external fluid, as stated by process requirements and conditions. According to flow-rate, the fluid can be filtered in one or more skid mounted parallel banks, connected by common headers.

GSV: Blow-Back filters tailor made

HyPulse GSV filtration system are fabricated in cooperation with Mott Corp. and are suited for separation of catalysts and solids from gas streams. GSV filtration system are designed for automatic operations, minimizing or eliminating the maintenance cost. The HyPulse GSV systems are intended for critical application or high temperatures (exceeding 900 °C).

HyPulse GSV filtration system are fabricated in cooperation with Mott Corp. and are suited for separation of catalysts and solids from gas streams. GSV filtration system are designed for automatic operations, minimizing or eliminating the maintenance cost. The HyPulse GSV systems are intended for critical application or high temperatures (exceeding 900 °C).

LSI: Back-Pulse filters tailor made

HyPulse LSI filtration system are fabricated in cooperation with Mott Corp. and are suited for separation of catalysts, activated carbons and solids from liquid streams. LSI filtration system are designed for automatic operations, minimizing or eliminating the maintenance cost. The HyPulse LSI systems are intended for critical application or high temperatures (exceeding 900 °C).

HyPulse LSI filtration system are fabricated in cooperation with Mott Corp. and are suited for separation of catalysts, activated carbons and solids from liquid streams. LSI filtration system are designed for automatic operations, minimizing or eliminating the maintenance cost. The HyPulse LSI systems are intended for critical application or high temperatures (exceeding 900 °C).

• Alkylation

• Ammonia production

• Aromatics production

• Biodiesel

• CCR

• Crude Distillation

• Dehydrogenation

• FCC

• Hydrotreating

• Hydrocracking

• Hydrogen peroxide production

• Hydrogenation

• Isomerization

• LTG

• Natural gas

• Nitric acid

• Olefi ne cracking

• Off-shore applications

• Power generation

• Polypropylene production

• Polyethylene production

• Teg regeneration