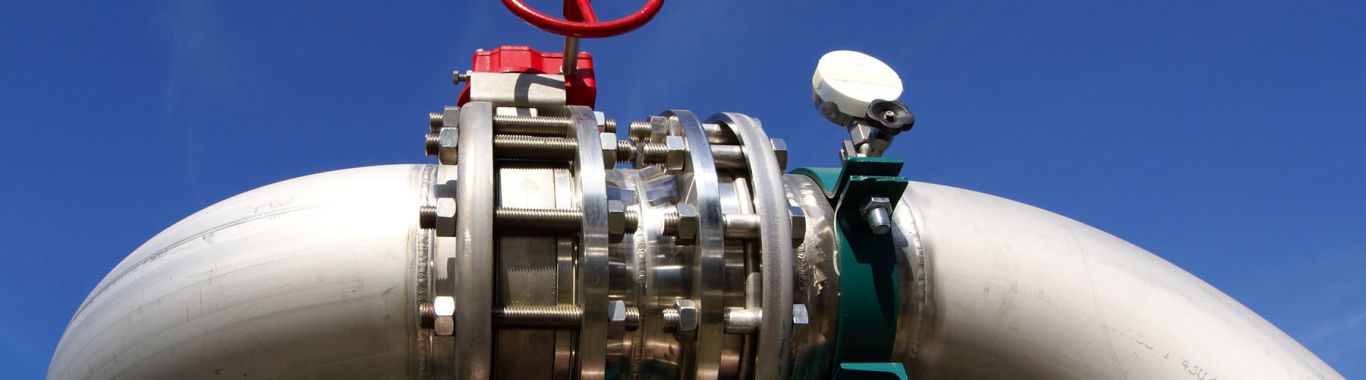

HiPer™ Bulk Deoiler Hydrocyclone and HiPer™ Deoiler Hydrocyclone

- Meeting the stringent performance requirements given by environmental legislation

- Minimum pressure drop and stable oil-from-water separation

- Easy disassembly and cleaning

Main applications

- Oil and gas industry

Technology

Conventional deoiling hydrocyclones with tangential inlet ports have long been part of produced water treatment facilities. With environmental legislation around the world increasingly sharpening the allowable oil-in-water content to maximum 20 ppm or even below, the conventional designs are often not adequate to meet these stringent regulations.

Contrary to tangential or axial inlet hydrocyclones, the operating principle of these MixedFlow types, with multiple inlet ports positioned at the periphery of each individual cyclone liner, results in a stabilizing and coalescing effect on the water/oil flow. Most available pressure energy is converted in to a rotating motion within the cyclone. This results in the generation of maximum G-force that will be responsible for an adequate and stable oil-from-water separation, combination with minimum pressure drop.

The mechanical design of each liner, with its removable top swirl section, allows for easy dis-assembly and cleaning. New vessels are minimized in size for a given pressure drop, thereby resulting in CAPEX savings.

Existing vessels with conventional liner types can be retrofitted with HiPer Deoiler Hydrocyclones to allow for more flow capacity at a given pressure drop or operation at the same flow rate with a resulting lower pressure drop.

As part of qualification programs for subsea separation systems, a 2-stage version of this system design has been extensively tested in low pressure and high pressure multiphase flow loops under realistic oil and gas field conditions, with varying feed conditions and oil characteristics.