MARKETS

ContraFlex® Cryogenic Jet Protection

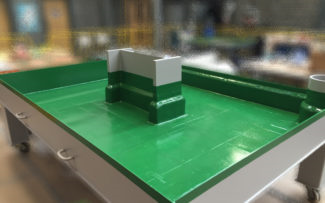

ContraFlex® cryogenic protection jackets have been specifically designed and tested to protect assets where there is a risk of cryogenic exposure in operating temperatures between -36 ̊C and +260 ̊C. Where insulation is required to protect against Cryogenic jet release, ContraFlex® CSP/PFP Jackets provide a removable solution to piping, flanges, and valves with minimal steel temperature drop during 60-minute cryogenic exposure at -196°C and can withstand up to 120-minutes jet fire.

Product specifications

ContraFlex® CSP/PFP jackets are tested to both hydrocarbon pool and jet fire scenarios (UL1709 and ISO22899) to provide protection up to 180 minutes in the event of a fire. The system is utilised across oil & gas, petrochemical, LNG and nuclear projects globally.

- Cryogenic jet release as per ISO20088-3 for 60-minutes, <5°C temperature drop on the steel substrate

- Simple installation using first-fit Velcro-type hook and loop fastening

- Remain effective in ambient conditions as low as -52°C

- 75mm thickness

- Jet fire protection as per ISO 22899-1 of up to 120-minutes on piping, flanges, supports and valve assemblies (directly after cryogenic exposure)

- ISO 22899-1 Hydrocarbon Jet Fire.

ADDITIONAL INFO

Cryogenic spill protection

Combined CSP and PFP or CSP only solutions to protect key structural elements from cryogenic spillage and jet fire.

Pipes manifolds and flanges

Fully bonded phenolic coating system, bespoke pre-cast shells and jackets.

Valve and actuator protection

Suitable for valve assemblies in petrochemical plants, LNG installations, power plants, chemical plants and more.

Vessel protection

Integrated thermal insulation, and passive fire

Combined CSP and PFP or CSP only solutions to protect key structural elements from cryogenic spillage and jet fire.

Pipes manifolds and flanges

Fully bonded phenolic coating system, bespoke pre-cast shells and jackets.

Valve and actuator protection

Suitable for valve assemblies in petrochemical plants, LNG installations, power plants, chemical plants and more.

Vessel protection

Integrated thermal insulation, and passive fire

SIMILAR PRODUCTS